-

Temperature Control Units (67)

-

Water Temperature Control Unit (43)

-

Oil Temperature Control Unit (70)

-

Mold Temperature Control Unit (43)

-

Hot Oil Temperature Control Units (29)

-

Air Cooled Screw Chiller (87)

-

Air Cooled Water Chiller (96)

-

Industrial Water Chiller (89)

-

Hot And Cold Unit (20)

-

FRP C Channel (7)

-

Mould Runner Cleaner (44)

-

FRP Square Tube (48)

-

FRP Round Tube (8)

-

FRP I Beams (4)

-

Pultruded FRP (10)

High Efficiency Electric Air Source Heat Pump With R134a Refrigerant

| Place of Origin: | China |

| Brand Name: | EuroKlimat |

| Certification: | AHRI ,CE,ISO9001,ISO14001,OHSAS18001 |

| Model Number: | EKAS0110 |

| Minimum Order Quantity: | 2pcs |

| Price: | negotiation |

| Packaging Details: | Plywood |

| Delivery Time: | 40 working days after received your payment |

| Supply Ability: | 60pcs per month |

|

Detail Information |

|||

Product Description

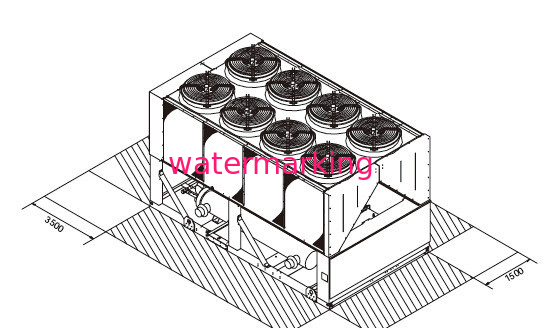

Ultra High-Efficiency Screw-Type Air-Cooled Chilled Water (Heat Pump) Unit R134a Refrigerant

Overview

Over half a century of innovation and development, EK air conditioning air-cooled heat-pump technology has become the leading technology in the global industry. EKAS screwtype air-cooled chilled water (heat pump) unit originates from the air-cooling kingdom, Italy, and inherits the Europeleading large-scale air-cooled unit design achievements, and adopts the new-generation R134a special screw technology. The unit optimizes system configuration and delivers stable and reliable performance, providing the highest energy efficiency (EER3.48) in the industry.

![]()

Features

1. Patent dual screw compressor delivering high efficiency at low noise

The latest generation HFC-134a dedicated dual-screw compressors developed by EK Italy are adopted, and brand new gap and oil injection design is used to fully improve full-load and load-drop running efficiency. The patent slider design helps improve the running efficiency at partial load by up to 15%. The unit has passed various certification tests such as EU security regulation certification CE mark, EU pressure container certification PED, US lab national certification UL, and CRAA certification, and provides guaranteed long-term high-efficiency safe and reliable running.

2.High-efficiency heat exchanger with outstanding performance

■ The heat exchanger for EKAS screw-type air-cooled chilled water (heat pump) unit adopts patent refrigerant distribution design and passes strict certification of EU and US ASME.

The internal heat exchange pipe uses high-efficiency internal threaded heat exchange copper tube to strengthen thermal conduction at the water side and refrigerant side, maximizing thermal conduction efficiency, reducing energy consumption of the unit, and reducing customer running expenses.

■ The standard piping mode provided by the heat exchanger is trough coupling connection (with short tube), facilitating field installation. Each evaporator and condenser is equipped with independent air exhaust and water drainage devices.

■ The heat exchanger facilitates compressor oil return design for simple oil return without an oil pump, eliminating the risks of a frozen heat exchange pipe. The heat exchanger requires a refrigerant filling amount that is only 1/3 compared with an ordinary heat exchanger, and does not leak, making it

environment-friendly and reliable.

3.New economizer

The unit adopts a brand new economizer circulation design.

The electronic expansion valve implements precision control,increasing the over-cooling degree of the unit, and greatly improving the cooling capacity and cooling efficiency of the unit.

4.Stable and precise control through electronic expansion valves

The full series units adopt electronic expansion valve control technology with independent power supply. The design of dual power supply implements optimal control for superheating and ensures high-performance running of the unit. The precise PID flow control through electronic expansion valves

allows stable refrigerant control, protects the compressors, and monitors air exhausted by compressors, avoiding faults of compressors.

5.Patent aerofoil screw fan providing large air flow and low noise

■ The unit fan adopts aerofoil low-noise fan design to![]()

control air interference, produce a large air flow, and efficiently reduce the fan noise.

■ Optimized bent impeller front-end design suppressesair eddy at the edge of the fan impellers, improves the rotation efficiency, and reduces the noise.

■ Idle running of the motor is eliminated, and overheat protection is implemented, prolonging the lifecycle.

■ It is directly driven by the motor, which eliminates transmission loss and reduces vibration.

■ A high-static-pressure fan motor is optional, meeting requirements of various scenarios for static pressure.

6. Environment-friendly

■ The environment-friendly R134a refrigerant delivers outstanding performance, saves electricity, contains no chlorine, does no harm to the atmospheric ozone layer, and therefore has an unrestricted term of use.

■ The emission of CO2 is efficiently reduced, alleviating the increasingly severe urban heat island effect and enabling green buildings .

7.Wide running range and long lifecycle

■ The shell of the unit adopts electro-galvanized sheet and is electrostatic sprayed with anti-erosive coating, which effectively prevents rust and adapts to various harsh outdoor conditions.

■ The unit adapts to a wide atmospheric temperature range from -10 ºC to 50 ºC.

■ Efficient automatic precise defrosting is implemented, prolonging the lifecycle of the unit.

■ The unit directly exchanges heat with the atmosphere, producing no pollution

8. Centralized Control

EK centralized control system adopts the industry-leading control solution. The product configuration is applicable to the chilled pump control system solution. Multiple persons are allowed to control and monitor the unit on the homepage of a Microsoft-based web browser.

The international general RS485 standard serial communication interface is adopted. Joint connection with other building access systems (BASs) is supported through the communication protocol conversion module (optional) provided by EK to implement group control on multiple units. The standard protocols include BacNet, Modbus, and Lonwork.

![]()

9.Comparison between electronic expansion valve, heat expansion valve, and orifice control valve

![]()