-

Temperature Control Units (67)

-

Water Temperature Control Unit (43)

-

Oil Temperature Control Unit (70)

-

Mold Temperature Control Unit (43)

-

Hot Oil Temperature Control Units (29)

-

Air Cooled Screw Chiller (87)

-

Air Cooled Water Chiller (96)

-

Industrial Water Chiller (89)

-

Hot And Cold Unit (20)

-

FRP C Channel (7)

-

Mould Runner Cleaner (44)

-

FRP Square Tube (48)

-

FRP Round Tube (8)

-

FRP I Beams (4)

-

Pultruded FRP (10)

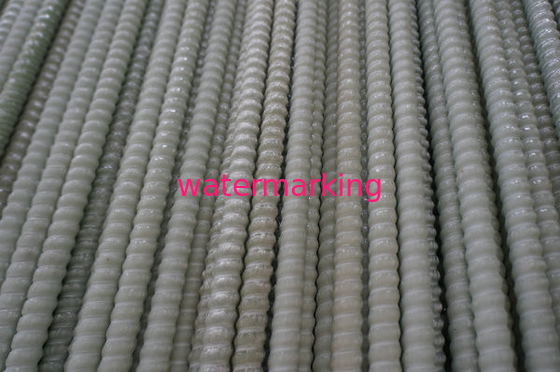

Fiber Reinforced Polymer Pultruded FRP Rebar Anti - Corrosion Plastic GRP Rib

| Place of Origin: | Hubei, China |

| Brand Name: | Yulong |

| Certification: | ISO9001,ISO140001 |

| Others: | Customized colors and dimensions |

| Minimum Order Quantity: | 1*20ft |

| Price: | EXW, FOB, CNF, CIF |

| Packaging Details: | Plywood pallet with plastic wrapped for packing |

| Delivery Time: | About 5-10 days after deposit received |

| Payment Terms: | TT,L/C, Western Union, Money Gram |

| Supply Ability: | 6000m/week |

| Port: | Yichang Port |

|

Detail Information |

|||

Product Description

Fiber Reinforced Polymer FRP Rebar Anti - Corrosion Plastic GRP Rib

Features:

- Corrosion resistant

- High strength & light weight

- Long service life

- Fire retardant

- Impact resistant

- Nonconductive and thermal insulation

- Non-magnetic electromagnetic transparency

- Dimensional stability, Bright color

- Low-maintenance

Pultrusion Technique:

During the pultrusion process, the raw materials are pulled through a heated steel forming die using a continuous pulling device. FRP Pultruded Profile are made of different resins reinforced with fiberglass, by pultrusion technology.

![]()

Physical Property:

|

Product name: |

Pultruded FRP Rebar |

|

Place of Origin: |

Hubei, China |

|

Brand Name: |

Yulong |

|

Dimension(mm): |

Customized dimension & colors are both available. |

|

Raw Materials: |

|

|

Color: |

Grey, Blue, Yellow, Red, other customized colors |

|

Density: |

1.5-2.0 g/cm3 |

|

MOQ: |

1*20ft |

|

Price: |

EXW, FOB, CNF, CIF |

|

Port: |

Yichang Port |

|

Packaging Details: |

Plywood pallet with plastic wrapped for packing |

|

Delivery Time: |

About 5-10 days after deposit received |

|

Payment Terms: |

TT,L/C, Western Union, Money Gram |

|

Supply Ability: |

6000m/week |

|

Diameter /mm |

Cross Section/cm2 |

Weight Kg/m |

Ultimate Tensile Strength/MPa |

Ultimate Shearing Strength/MPa |

E-Modulus/GPa |

|

4 |

0.12 |

0.032 |

1500 |

>150 |

>40 |

|

6 |

0.28 |

0.051 |

1280 |

>150 |

>40 |

|

8 |

0.50 |

0.098 |

1080 |

>150 |

>40 |

|

10 |

0.73 |

0.150 |

980 |

>150 |

>40 |

|

12 |

1.03 |

0.210 |

870 |

>150 |

>40 |

|

14 |

1.34 |

0.275 |

764 |

>150 |

>40 |

|

16 |

1.80 |

0.388 |

752 |

>150 |

>40 |

|

18 |

2.48 |

0.485 |

744 |

>150 |

>40 |

|

20 |

2.78 |

0.570 |

716 |

>150 |

>40 |

|

22 |

3.55 |

0.700 |

695 |

>150 |

>40 |

|

25 |

4.78 |

0.970 |

675 |

>150 |

>40 |

|

28 |

5.90 |

1.195 |

702 |

>150 |

>40 |

|

30 |

6.71 |

1.350 |

637 |

>150 |

>40 |

|

32 |

7.40 |

1.520 |

626 |

>150 |

>40 |

Application:

- Electrical & Electronics Industry: cable tray, radome, insulation ladder, etc.

- Chemical Anti-corrosion Industry: grating floor, handrail, working platform, underground pression pipe, stairs, etc.

- Building Construction Industry: oversize bridge protection closed system, movable house structure, working platform, window frame, window sash and its components, etc.

- Foundation Engineering Industry: freeway antiglare shield and its handrail, lamp post, water treatment, bracket foe huge industry cooling tower, etc.

Why should you choose us?

- We are manufacturer and exporter of fiberglass reinforced pultrusion profiles.

- Our company was established by Yulong Group and with 12 automatically production lines, which will assure large output and prompt delivery for you.

- Our R&D team is with 2 professors, 3 senior engineers and 8 doctors, possessing 16 advanced technical patents. In 2012, our company established a technical research center with HUST (Huazhong University of Science and Technology) to develop and utilize the FRP new materials.

- Our company has passed the quality management system of ISO9001, ISO14001.

- Strictly raw materials and production quality control system is the strongly guarantee of high quality products.

- Strong human resources and management are also one of our advantages.

- Our other FRP composite products are pultrusion fiberglass square tube, frp channel, frp beams, frp round tube, frp flat bar, frp angle, frp cable tray, frp rod, frp rock bolt, frp rebar, frp mortar pipe and other frp profiles.

Advantages of fiberglass composite products:

- Pultruded glass fiber reinforced structural shapes and plate have a number of significant advantages over materials such as timber, steel, and aluminum in many structural, electrical, and environmental applications. Pultruded fiberglass is highly corrosion resistent and will not rot or decay and is not susceptible to insect attack. Unlike wood, fiberglass requires no environmentally unfriendly preservatives or repellants, does not absorb any significant amount of water and is consistent in strength and appearance piece-to-piece (no culling). Pultruded fiberglass is stronger, more rigid and lighter weight than structural timber. Pultruded glass fiber reinforced structural shapes and plate are electrically and thermally non-conductive, impact resistant, and EMI/RFI transparent.

- Contact us for more details.

![]()

![]()

![]()

![]()